Job Opportunities

We Currently have openings for the following positions:

Reasons to work for Empower RF Systems

1.

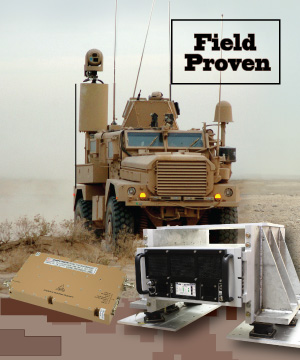

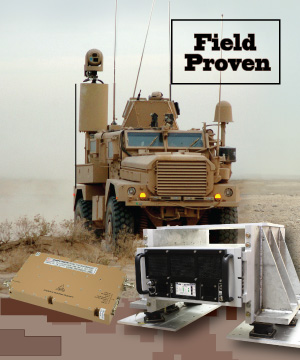

High power, solid state RF is on the forefront of technology advancements in mission critical applications.

2.

The team at Empower RF Systems is doing leading edge design work to enable the deployment of next generation power amplifiers and the embedded computing that’s integral to their performance advantages.

3.

If you are tired of working on legacy designs, sustaining old systems, or otherwise laboring with limited prospects for intellectual or career advancement, you need to find out more about what we are doing and who we are hiring. We have immediate needs for qualified, high power RF engineers and technicians, and qualified test engineers - come join our team and jump to the leading edge of solid state, high power RF.

4.

Patented technology

US Patent 8,736,365 B2

US Patent 9,093,731 B2

US Patent 9,007,125 B2

US Patent 11,115,121 B2

US Patent 20,200,366,258 A1

Empower RF Systems, Inc., a leading provider of high-power ultra-broadband radio frequency (RF) amplifiers is seeking qualified, dynamic, successful and driven candidates.

Founded in 1999, Empower RF Systems designs and manufactures solid-state, high-power RF amplifier systems and modules for commercial and military customers worldwide.

We are an ISO9001 certified company with an excellent industry reputation. New employees are hired with an eye toward their future growth potential and capability to contribute to this fast-paced work environment that encourages engineering innovation and customer satisfaction.

We offer a competitive salary, cash bonus plan, comprehensive benefits including Medical, Dental, Vision, 401(k) contributions, etc. As an Equal Opportunity Employer,

we are committed to a diverse workforce. If any of these position descriptions sound like you, we welcome your response!

Equal Employment Opportunity

Reasonable Accommodation

Right to Work Statement

Empower RF Systems is an IMAGE member and participates in E-Verify Details

Engineering

Associate RF Engineer

Job Summary

Reporting to the Chief Technical Officer and Sr. Systems Engineer, the Associate RF Engineer will participate in the process from proposal to end of life in the design, development, and maintenance of high-power Solid-State Amplifiers and Systems. The incumbent will work with other engineers, managers, QA, and Operations teams to develop innovative solutions that meet market needs with respect to functionality, performance, scalability, reliability, realistic implementation schedules, and adherence to development goals and principles.

Essential Functions

- RF high-power solid-state amplifier design, using 1 MHz to 6 GHz simulation design tools, such as HFSS, AWR MWO and ADS, and using LDMOS, GaAs and GaN devices to > 1000W.

- Design and perform amplifier characterization under high-power conditions and the interaction of the amplifier integrated into the amp assembly.

- Perform circuit analysis on simple to medium complexity analog, digital, and RF circuits.

- Generate test procedures and schematic diagrams. Assist in design reviews under the guidance of senior engineers.

- Provide support to the Engineering Organization as directed.

- Resolve technical problems during test and integration phases.

- Generate and review technical product documentation, including written documentation instructing customers in the use of delivered products.

- Establish product design criteria, and determine material requirements, operational capabilities and limitations.

- Responsible for project management of his/her designs and assure the workflow hand-offs within the company.

Key Qualifications

- Associate or Bachelor’s degree in Electrical Engineering required or equivalent experience.

- Two to three years of work experience within an RF/Microwave/Aerospace Engineering environment.

- Strong educational foundation that includes coursework and lab work in RF/Microwave theory and principles.

- Knowledgeable in digital and analog electronics. Strong desire to learn and contribute in a fast-paced environment.

- Experienced in the use of RF/microwave measurement instruments such as spectrum analyzers, network analyzers, signal generators, and oscilloscopes.

- Ability to interface with the customer, manufacturing, test, and subcontract technical personnel.

- Knowledge of device/device technology. Skilled in design, validation and characterization of analog circuits.

- Must be a flexible and motivated team player who is able to prioritize tasks and communicate effectively.

Apply for this position

Operations

RF Test Technician

Job Summary

Reporting to the Operations Manager and partnering closely with engineering teams, the RF Test Technician develops and performs test solutions for RF products from concept through manufacturing release. He/she supports product development evaluations and final product characterization testing and works with the development team.

Primary Duties

- Work closely with product design engineering and operations to support product development.

- Specify and recommend test resources, processes, capabilities, and technology.

- Set-up test circuits to measure the electrical parameters of products.

- Test, update and repair printed circuit board using test stations, soldering equipment and/or tools.

- Participate in the assembly and testing of RF components within manufacturing.

- Use basic statistical tools, compare to charts, histograms, cause-and-effect diagrams, to evaluate electrical data for test variability and aid in problem solving.

Qualifications

- Associate Degree in Electrical Engineering, trade school education, electronic certification, or equivalent professional training with 3 years of experience in RF testing and basic manufacturing assembly skills.

- Capable of setting and adjusting each electrical test instrument and measuring the magnitude and accuracy of the parameters called out by the specification.

- Able to make complex test set-ups including inputs, outputs, and metering requirements.

- Basic RF knowledge needed, along with tuning/troubleshooting experience from 6GHz and below.

- Ability to debug circuits and systems.

- Hands-on experience with RF testing equipment including Spectrum and Network Analyzers, Oscilloscope, Power Meter, Signal Generator, and Power Supply.

- Awareness of ISO 9001 standards and procedures.

- Comfortable working both independently and in team environments.

- Excellent communications skills; computer proficiency; good analytical and problem-solving skills.

- Must be able to walk, sit or stand throughout an 8-10 hour day, and lift 40 lbs. using proper technique.

Apply for this position

Electronic Assembler

Job Summary

The Electronic Assembler provides the skill set and knowledge to properly configure complex RF power amplifier assemblies. Experience needed in RF components, RF devices, assembly techniques especially printed circuit boards for power amplifiers, including coaxial transformers, ferrites, and all RF related passive components. The Electronic Assembler makes all electrical harnesses and RF coaxial cables; includes soldering, wiring, mechanical and electrical assembly.

Essential Functions

- Works from production assembly instructions, schematics, rough sketches, and verbal instructions or notes to assemble, wire and install a wide variety of complex mechanical assemblies.

- Performs various cable assembly operations on shielded cables, ribbon cables, and wire harnesses.

- Performs operations such as assembling units of high complexity including printed circuit boards, modules, chassis, cable harnesses and similar tasks.

- Typical cable assembly tasks include cable cutting, jacket removal, shield preparation and termination, ribbon cable preparation and termination, and stripping, tinning and termination of wire harnesses.

- Performs a variety of miscellaneous shop work and other duties as assigned by supervisor.

- Responsible to keep clean, orderly, and safe work areas.

- Works with hand tools such as soldering iron, wire strippers, crimpers, wrenches, screwdrivers, and power tools.

- Assists in reviewing documentation including assembly prints, part lists, and mechanical prints related to building and testing hardware.

Qualifications

- Requires two or more years of assembling electrical parts, and familiarity with RF connectors.

- Must have previous training in IPC J-STD-001 and IPC-A-610 certification or equivalent.

- Must be able to read, write and speak basic English, perform basic math, and follow instructions.

- Must be able to read and understand assembly prints, parts list, wiring diagrams and wiring lists. Schematic familiarity and understanding of part numbers, polarity designations, color codes, etc.

- Manual dexterity required. Bending, stooping and lifting are performed daily. Capable of lifting 30 pounds from floor to bench using a proper lifting technique.

- Must be able to walk, sit and/or stand throughout an eight or ten-hour day.

- Position requires use of hand tools, power tools, and soldering irons in order to complete quality product.

- Must be able to work on prototype, engineering and production type hardware, rough sketches, and verbal instructions or notes to assemble, wire and install a wide variety of complex mechanical assemblies.

- Familiarity with manufacturing Quality and Inspection processes is a plus.

Apply for this position